seal integrity testing|sealing problems in packaging : wholesaling 5.1 Seal attributes can be linked directly to a number of variables in process parameters, equipment, or material, as well as environmental (room temperature and relative . ავერსის ბრენდები

{plog:ftitle_list}

Estreia Mundial: 23 de Setembro de 2021. Outras datas. Elenco de Lei & Ordem: Unidade de Vítimas Especiais (23ª Temporada) Mariska Hargitay Olivia Benson. Alexander Koch Nick Pearce. Ben Rappaport Congressman George. Ice-T Odafin Tutuola. Joseph Cannon Arlo James. Mais. Denunciar algo errado. Em Breve.

Testing the integrity of package seals helps ensure that food packaging provides required product protection. Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently assessed with seal integrity tests.The integrity of seals on packaging for new product introductions and alternate . Six new reasons drive home the importance of determining seal integrity using these common food packaging test methods.

The integrity of seals on packaging for new product introductions and alternate distribution, such as via e-commerce, also needs to be assessed. Maintaining the reliability of package seals is . 5.1 Seal attributes can be linked directly to a number of variables in process parameters, equipment, or material, as well as environmental (room temperature and relative .Explore the seal integrity test, its importance in packaging, and how Jacob White Packaging ensures product safety and quality through rigorous testing procedures.Seal strength testing evaluates the mechanical strength of the seal, assuring proper bonding to maintain package integrity throughout the life of the package. Package integrity implies the .

CCI Testing to Support Product Packaging. Employ our container closure integrity (CCI) testing programs to provide accurate, sensitive, and reliable data regarding your product packaging .ASTM F1886 is the standard test method for determining the integrity of seals for flexible packaging by visual inspection. Specifically, this ASTM package validation standard covers the .Packaging integrity and seal strength testing are key validation requirements for terminally sterilized medical devices, and demonstrate that the package has retained its seal strength and has no breaches or defects following .Seal integrity testing also helps us verify the performance of seals under actual operating conditions. This includes testing the seal’s ability to withstand pressure, temperature, and other environmental factors, as well as its ability to maintain a proper seal over time. It’s like putting a seal through a fitness test to make sure it’s .

Seal integrity testing, on the other hand, evaluates the material’s performance as a whole, determining the quality of the complete, finished package rather than simply testing part of the package as is seen in seal strength testing. Seal integrity testing will ensure that your package can withstand a variety of pressures, maintain .The Sepha PakScan is a non-destructive test method. The machine performs a dry seal integrity test enabling manufactures to recover packs that have passed the leak test and return them to the production line. The system can identify .

Overview: ISO 838 focuses on the seal integrity testing of packaging used for various products. This standard provides methods for evaluating the effectiveness of seals in maintaining product protection against external contaminants. Applications: It applies to packaging in different industries, including pharmaceuticals, food, and medical . From primary seal testing through to pallet-level transit testing, Eurofins Medical Device Testing network of laboratories' state-of-the-art package testing facility provides complete capabilities for evaluating every aspect of your package and labelling configurations, to ensure your product will survive the rigors of being transported around .Seal strength package integrity testing is crucial in preserving the quality and integrity of products. Properly sealed packages prevent contamination, spoilage, and degradation due to environmental factors such as moisture, oxygen, and light. By evaluating the seal’s strength, the testing process ensures that packages effectively protect the .

PTI’s proprietary Airborne Ultrasound technology is a non-destructive and non-invasive seal quality inspection method. This is a referenced technology in the new USP <1207> Chapter Guidance as a deterministic test method for seal quality testing, an ASTM Test Method F3004 and FDA Recognized Standard for seal quality integrity testing. Know moreGet efficient leak, seal, and burst testing of your packages for total package integrity Package leak detectors ensure that seal integrity problems are identified. This is a vital part of Modified Atmosphere Packaging (MAP) quality control, since compromising the protective atmosphere will cause a reduction in the shelf-life of MAP products .The benefits of deterministic container closure integrity methods are plentiful, and their usage can span the entire lifecycle of a product-package system, right from development of the package, assembly validation, to stability, to analysis of package integrity after distribution cycles.

Seal integrity tests assess the production line sealing parameters and measures the level of protection the flexible packaging provides to the products inside. Maintaining the reliability of the seal quality of flexible packages is critical in ensuring the quality and safety of the products. Seal attributes of flexible packaging are dependent .

By adhering to this standard, you ensure your packaging meets the necessary seal integrity testing requirements for sterile products. Both ASTM F88 and ISO 11607 play vital roles in maintaining packaging seal strength across various industries. By following these standards, you’ll ensure your seal strength testing methods are compliant .The CS Analytical team are experts when it comes to all types of seal integrity testing for Pharmaceutical, Medical Device and Biotechnology products and package systems. The team has the experience to understand all aspects of the relevant ASTM procedures and how they apply to these unique, and often sensitive, product types. .

These parameters have a key role on the melting of the sealant film layer and the fusion of the molten surfaces. Seal quality is defined by the requirements of product sensitivity, design and easy usage requirements. Good sealing is a concept that indirectly measured via various methods such as Hot-tack, T-peel and leak detection tests.

Seal strength testing evaluates the mechanical strength of the seal, assuring proper bonding and providing an indicator of package integrity throughout the life of the package for a variety of pouch package systems holding drug product or medical devices. Burst testing is a leak detection and seal integrity testing method to determine the level of pressure packaging can withstand. It involves inserting a needle probe through a self-sealed, adhesive-backed septum and inflating the .Leak detection and seal integrity testing are critical for ensuring product packaging is devoid of defects, such as punctures, pinholes, or channel leaks, that could result in leaks. This evaluation is essential for identifying .

gas permeability tester polymer

Seal strength integrity testing is a method to determine the efficiency of seal packages. Learn more about the seal strength test and how it is done. Testing for seal strength determines how strong seals are in flexible materials. The .Perform seal integrity and leak tests according to approved procedures. Document test results accurately. 3.2 Quality Control (QC) Analysts. Verify and validate seal integrity testing methods. Review and approve test results.A Powerful Vial Seal Quality Test Carolina González Gaitán, PhD Parenteral Packaging Scientist Genesis Packaging Technologies 2023 PDA Container Closure Integrity Testing –Basic Course Apr 20 –21, 2023 Lido di Venezia, Italy. 2 Agenda 1. Seal quality tests 2. Characterizing a “well-sealed” vial 3. RSF

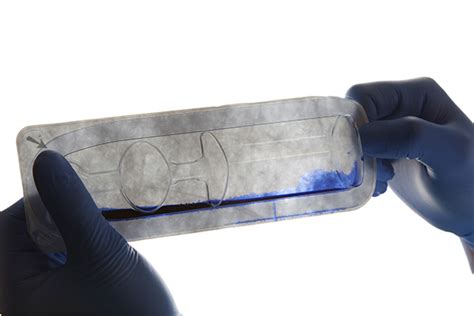

ASTM F1929 “Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration” is a dye penetration package integrity test used by package engineers that is designed to detect and locate leaks caused by channels formed between a transparent film and a porous material.. The ASTM F1929 standard was first written in 1998, was reapproved in 2004, .Seal Strength (Pack Integrity) Testing Test conditions based on ASTM F88 . ASTM F88 - Standard Test Method for Seal Strength of Flexible Barrier Materials . Seal strength is a quantitative measure for use in process validation, process control, and capability. Seal strength is not only relevant to opening force and package integrity, but to . Product Description. Pouch Seal Integrity Test : Designed to test the integrity of seals on either paper/poly or Tyvek® /poly packaging material, the Pouch Seal Integrity Test checks for an intact seal, punctures, tears and open seals of heat seal and self-seal pouches. The Pouch Seal Integrity Test is packed in an aluminum package to protect the ink against .• Test fixture or restraint mechanism at test sample site of contact may block leak path • Outgassing of sorbed gas on test sample surface (helium tracer test) or release of entrapped air pockets (bubble emission test) may falsely simulate leakage • Several minutes to weeks per test sample. Probabilistic Leak Test Methods. 11

Blow-fill-seal (BFS), Form-Fill-Seal (FFS), Small and Large Volume Parenteral (SVP & LVP) bags, glass or plastic ampoules, should be subject to 100% integrity testing. Samples of other containers closed by other methods should be taken and checked for integrity using validated methods. The frequency of testingStrength tests include seal peel and burst testing. Integrity tests include bubble emission and dye migration, however additional packaging testing for integrity are also available. Our packaging testing is done in compliance with criteria . Alternatives to sterility testing as part of the stability protocol, such as replacing the sterility test with container and closure system integrity testing, might include any properly validated .

Testing seal integrity is crucial for packed products. When a seal of your products is compromised, the loss of protective atmosphere starts a chain reaction. This results in customer complaints, costly returns and whole batches of products wasted.

sterile seal strength testing

sealing strength test

Resultado da 25 de jul. de 2022 · Depois de ter completado 53 anos, a cantora quis mostrar que a idade é apenas um número. Na lua de mel em Paris, Jennifer Lopez posou nua para campanha da sua marca e anunciou que mudou de apelido.

seal integrity testing|sealing problems in packaging